Repairing

My Old Friend's Old Anvil

My old friend, Eddie Wilson, K4UN, brought this old anvil to me and asked if I could mill a flat where the old hardened plate had broken out. It barely fit on the mill table with enough clearance for an end mill to extend out of the collett. These pictures will give you an idea of how the job went.

(Click on the thumbnail pictures to see a larger picture in another browser window)

My old friend, Eddie Wilson, K4UN, brought this old anvil to me and asked if I could mill a flat where the old hardened plate had broken out. It barely fit on the mill table with enough clearance for an end mill to extend out of the collett. These pictures will give you an idea of how the job went.

(Click on the thumbnail pictures to see a larger picture in another browser window)

| Here's the anvil before any work was done. Notice the break out of the top surface. There is actually some writing on the side of the anvil I can't make out. Too old, too worn... so is the anvil ;) | |

| Here's the breakout. Note the curved broken end and the craters where the metal separated. | |

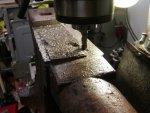

| I've clamped the vise onto the mill table and began some test cuts. | |

| It

seems to always happen... one bad cut, a ruined cutter and a gouge

that'll show. I had to re-tram the mill after this too. |

|

| Partially finished. Notice the crater to the left of the cutter. That is one of three significant places that the metal pulled out. One is just to the right and towards you from the cutter. The other is over to the left in the picture along the straight line near the edge of the anvil. | |

| Here's how I clamped the anvil to the table. | |

| Partially done I've got the end squared and located the deepest crater (lower right). | |

| Here the surface is flat. There is a small depression where the deepest crater was. We decided to leave this small depression rather than to mill any deeper below the horn. | |

| Here's the completed surface, anvil still on the mill. | |

| and here's the setup, inspiration and all. |